About HSS

The credible high volume 3D manufacturing solution

3D printing is now able to compete on price and speed with high volume injection molding, without the associated design limitations, upfront tooling, stock and shipping costs.

Typically 10 to 100 faster than current industrial 3D printing processes and with the potential to produce up to 100,000 parts a day, HSS makes 3D high volume manufacture of everyday products a reality, flattening supply chains and moving production closer to markets.

World-leading additive manufacture research, teamed up with market-leading industrial inkjet technology, makes this possible.

The HSS 3D print head has been especially developed from Xaar’s world-leading portfolio, proven in the most demanding high volume production environment of ceramic tile printing.

Our history

High Speed Sintering patents filed

Loughborough University files patents, supported by HEFCE, Higher Education Innovation Fund

Investigating a new manufacturing process

EPSRC funds preliminary investigation into a new manufacturing process - High Speed Sintering

Selective Absorption Sintering patent filed

Evonik Industries AG (Co-licensing partner ) files patent for key overlapping technology

First major grant awarded

EPSRC awards 2.5 year award to develop High Speed Sintering of Powders

First High Speed Sintering machine

Laser Sintering machine is retrofitted with Xaar’s print heads to create first High Speed Sintering machine

Ink development

Xaar sponsors research to develop new inks for High Speed Sintering

£1.2M funding

5 year award from EPSRC to develop High Speed Sintering for sport and leisure applications

Enterprise Fellowship

Loughbrough University awards first Enterprise Fellowship to Neil Hopkinson to develop High Speed Sintering, supported by HEFCE, Higher Education Innovation Fund

Breakthrough Technology Award

American Society of Manufacturing Engineers announce High Speed Sintering is a breakthrough technology

First dedicated High Speed Sintering machine

Design and manufacture of world's first dedicate machine is supported by HEFCE, Higher Education Innovation Fund

New patent filed

Loughborough University files new process improvement patent, supported by HEFCE, Higher Education Innovation Fund

First dedicated HSS machine delivered

World's first dedicated machine is installed at the University of Sheffield

Mechanical property development

Results presented from manufacture of highly ductile parts in elastomer materials

FACTUM project launch

Innovate UK awards major grant to develop High Speed Sintering for application across a range of industry sectors

Voxeljet manufacture first HSS machine

The world's first commercially manufactured machine is installed at the University of Sheffield

Functional part development

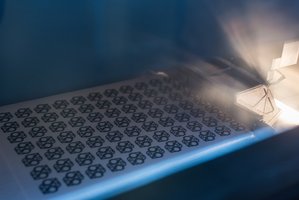

Results presented from manufacture of functional parts with properties controlled by varying greyscales

Fine feature upgrade

Xaar 1002 print heads added to HSS machine, enabling production of 0.5mm fine features

More licences granted

Several licenses to the HSS technology signed with industrial scale equipment manufacturers and sellers

Xaar expands its 3D business

Xaar announces plans for new 3D Centre in Nottingham, led by Neil Hopkinson

Xaar 3D Centre open for business

Centre opens to offer High Speed Sintering services for end users, OEMs and materials suppliers

voxeljet unveils High Speed Sintering process

Leading manufacturer of 3D printing systems for industry applications launches HSS technology in November

3D printing joint investment

Xaar joins forces with Stratasys to launch Xaar 3D Limited to develop 3D printing solutions based on HSS technologies

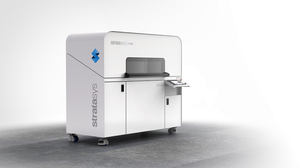

H350™ 3D printer launch

Stratasys introduces the Stratasys H350™ 3D printer, the first system powered by Xaar 3D’s powder-based SAF™ technology

Stratasys acquires Xaar 3D

Stratasys acquires outstanding stake in Xaar 3D to accelerate production-scale additive manufacturing capabilities